XCENTRIC HR82 600-1200 CLASS EXCAVATOR MINING HYD ROCK RIPPER

Oct 19th, 2023 at 20:56 Industrial - Machinery Langley 185 views Reference: 275Location: Langley

Price: $80,000 Negotiable

This was used on a PC650 Komatsu was equipped with this low-hour 2019 22000 LB MINING SERIES slightly used ripper for rock, coal, and sandstone.

ALSO GREAT FOR THE TOUGHEST PERMAFROST ON SLOPES, HILLS, AND HOLES THAT YOUR CRAWLERS CAN NOT ACCESS MAKES IT IDEAL FOR GOLD MINERS

XCENTRIC RIPPER SERIAL # 18062501; built in June 2018 in Italy; put into service in fall 2019; very little used because of COVID

The ripper has been upgraded with a reinforcing plate welded into a known weak spot on both sides of the main ripper shank.

The paint has been touched up, but those are the original factory decals on the ripper. The ripper requires nothing and is ready to operate.

CLEARER TITLE AVAILABLE NOW FOR WORK

SEE THE PDF FILE INSTRUCTION MANUALS FOR ALL DETAILS - COPY AND PASTE OR CLICK LINK:

https://www.shearforce.ca/wp-content/uploads/XR-MINING-SERIES-Instruction-Manual.pdf

https://bossattachments.com.au/wp-content/uploads/2020/05/boss-au-xcentric-ripper-xr.pdf

https://xcentricripper.com/wp-content/uploads/2019/05/FICHA-RIPPER-XR82_ENG.pdf

http://www.dbflimited.com/Resim/Upload/miningseriesripperenglish1.pdf

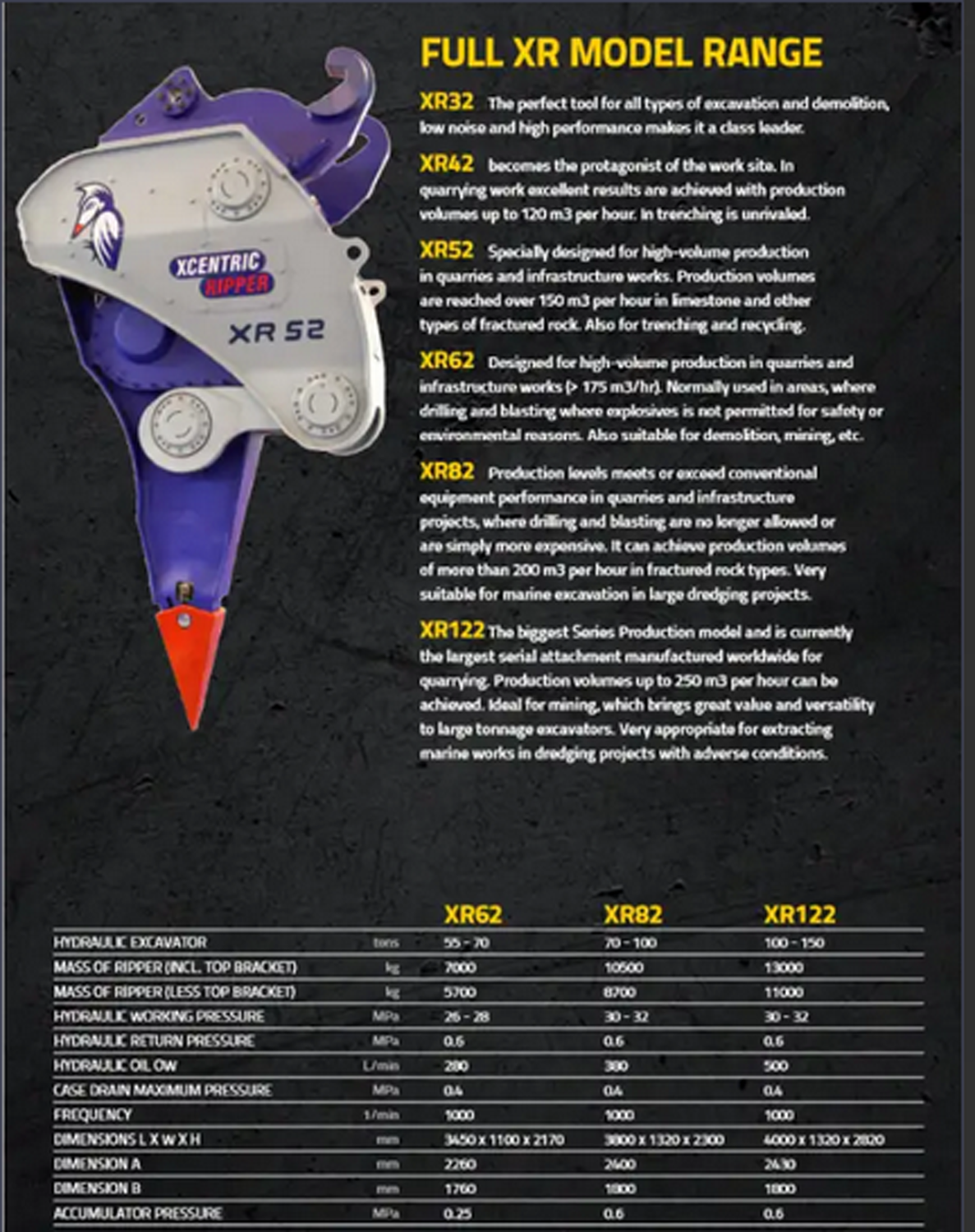

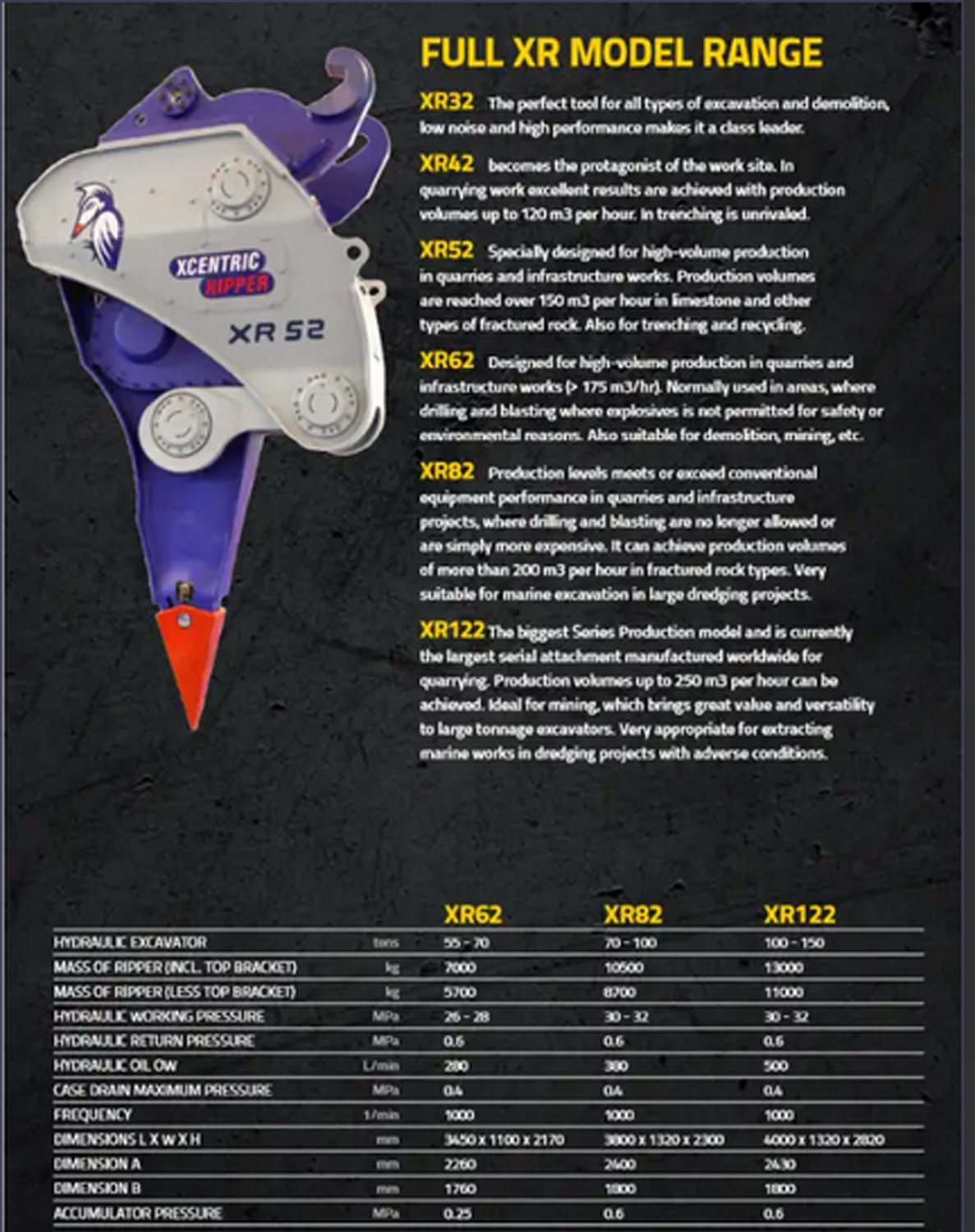

The XR82 key features as per Xcentric:

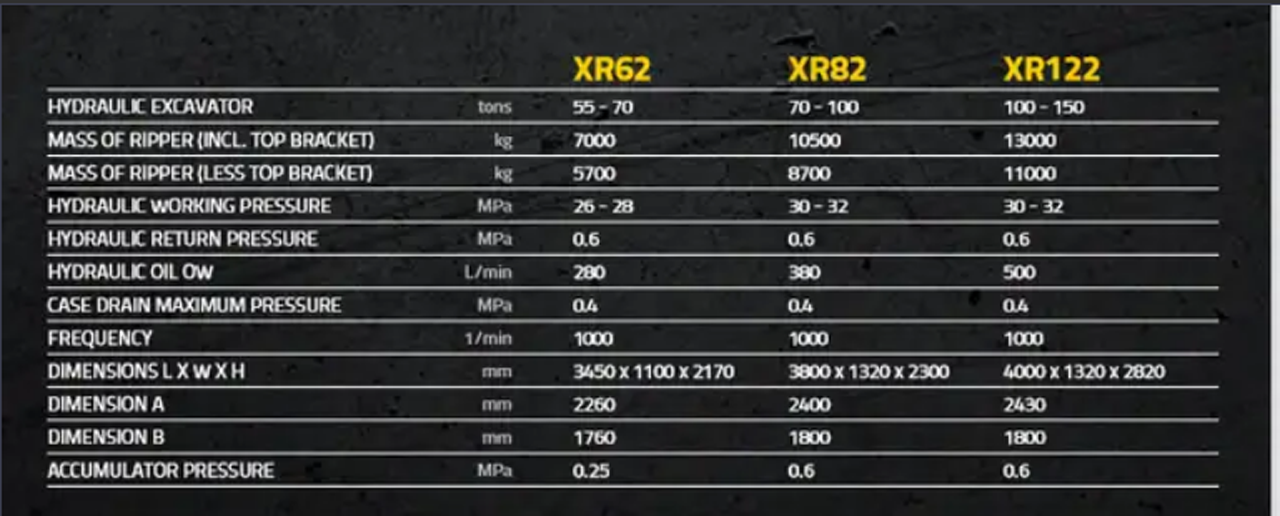

• Suitable for 70t-90t Excavators the XR82 weighs in at 10,000kg (WILL WORK ON 600 OR 650 CLASS WITH SHORT STICK HAS 120 MM MAIN PIN AND 110 MM SECONDARY PIN WITH 22.25 INCHES BETWEEN THE EARS)

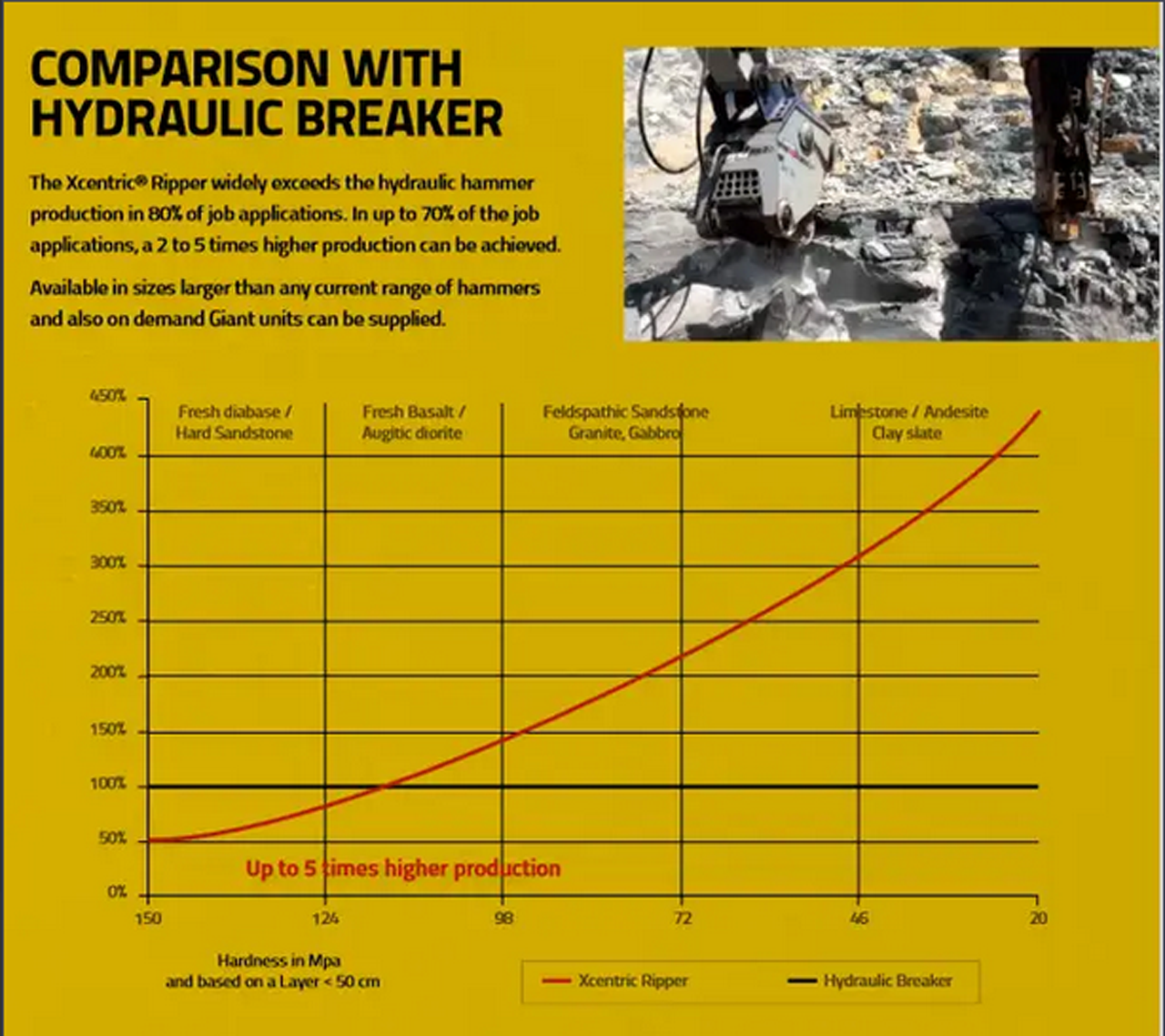

• 5 times higher production than conventional rock breakers

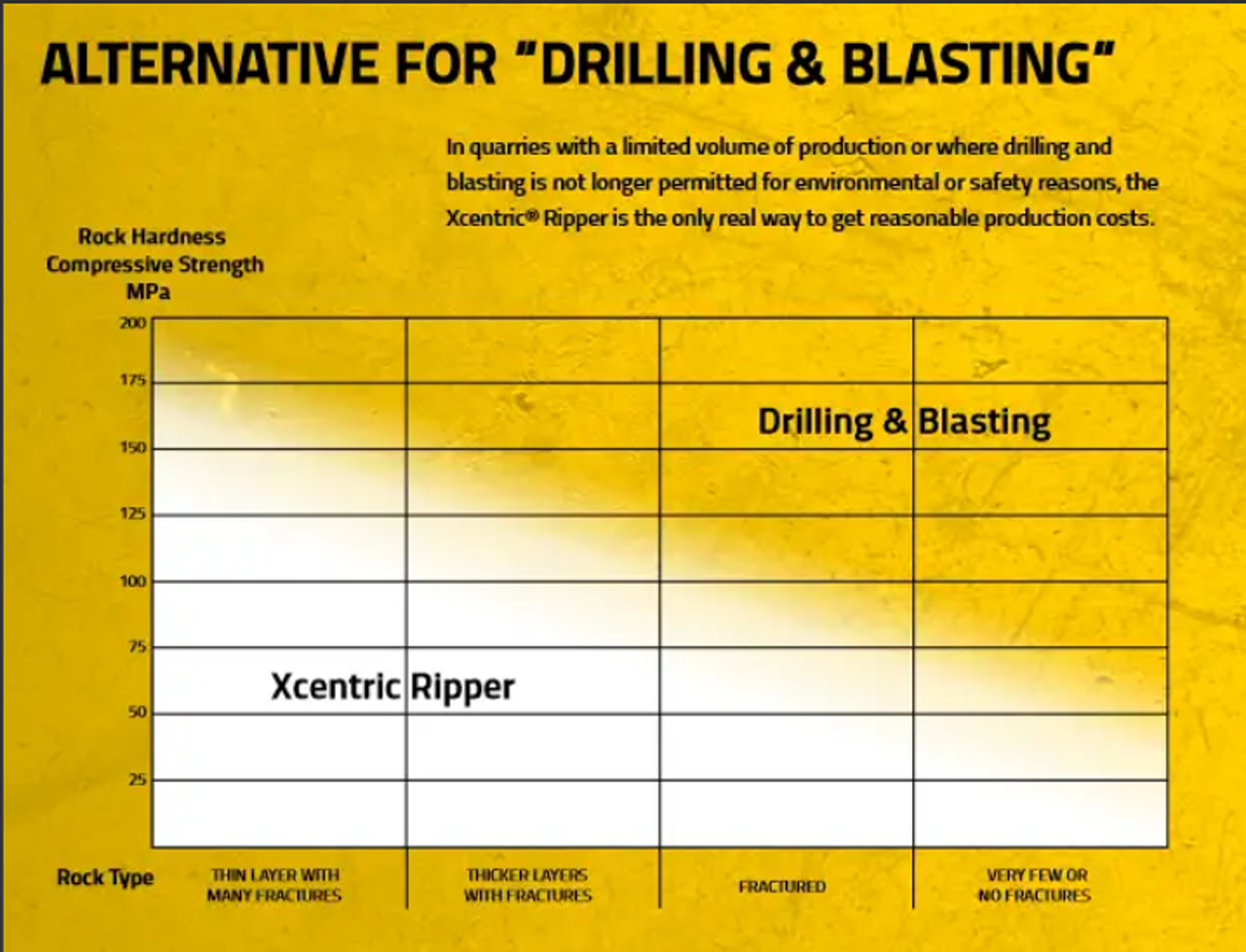

• A safe and easy alternative to drill and blast options

• New slim body design makes the XR Mining series perfect for trenching applications.

• Minimum noise levels

• Minimum maintenance

• No daily lubrication is required

• Minimum wear parts consumption

• Long-life components and materials

• Less fuel consumption per produced m3/ton

• Less emission per produced m3/ton

• Environmental protection (Bio Lubricants)

• Marine/underwater operation.

• Can be used on standard excavators.

• Increase operator comfort.

• HARDOX® & Strenx construction ensures long-lasting durability in extreme conditions.

• Designed and manufactured in Spain by Xcentric International, only the best materials are used for excellent quality. Solid, durable, and characterized by the now recognizable clean lines designed to resist wear and high stresses in the toughest working conditions.

• Extreme compactness and low center of gravity improves balance and drastically reduce the strain on the excavator's arm, eliminating impact vibrations.

Presenting the hydraulic ripper, the Xcentric Ripper®. A revolution in large-scale demolition and excavation.

The world's most productive, dependable, and technologically advanced hydraulic ripper has been developed over a decade and a half. With the introduction of the all-new Xcentric Ripper Mining Series, Xcentric International has raised the bar for the Xcentric Ripper range.

In almost every kind of material, the Xcentric Ripper® performs better than conventional hydraulic hammers, especially in medium-hard rock with natural fracturing and layers. The attachment takes advantage of the inherent rigidity of the rock by using its patented Impact Vibration Accumulation Technology. The vibrations this creates shake the material, deepening cracks for simpler breakup. It's a fantastic tool for trenching, dredging, underground mining, frozen ground excavation, demolition, rock excavation, slag recycling, and even underwater applications.

XR mining series range

• Easy operation with low noise.

• Unbelievable power and versatility.

• Easy on your machine’s pins and bushings.

• Low maintenance.

• Field replaceable ripper teeth.

• Patented impact vibration accumulation technology.

• A safe, easy, and environmentally friendly alternative to drilling and blasting options.

In order to prepare for a new harbor and breakwater for incoming marine traffic, one of our clients in the pile and dredging business needed an excavation tool that could be used for a three-month project that involved removing more than 40,000 yards of basalt from the shoreline.

After watching an online video of the new Xcentric Ripper Mining Series in action, the superintendent made the decision to give the more potent, new hydraulic ripper a chance to prove it was a worthy addition to their collection of excavation equipment.

He stated, "On one machine, we have the XR82 model operating, and on the other, we have a clamshell bucket for dredging." "We required a tool that would function effectively underwater, and thus far, the XR82 has lived up to our expectations. It's proving to be a useful addition to our fleet of equipment, and it performs admirably on some of our more specialized projects.

Upgrades to Mining Series Designs

The new Mining Series has been strengthened with a remodeled working platform, which delivers a much higher energy impact force to the work tool with a lower frequency, even though the working technology is based on the standard series. Larger, heavier eccentric gears are now made from a single steel billet and carefully engineered to distribute weight evenly side to side and channel impact energy vertically.

In order to reduce wear where the ripper usually comes into contact with the material, the lower pivot arm and housing have been reinforced, and the ripper arm or beak has been remodeled and strengthened using Hardox® steel. Additionally, the XR Mining Series' narrower body profile makes it perfect for tunneling and tight spaces.

High-volume rock excavation is about to undergo a revolution with the all-new XR Mining Series, which is designed to increase production at lower operating costs and noise levels. Similar to the standard series that preceded it, the Mining Series will be a priceless resource for pipeline trenching, demolition, slag recycling, dredging, oil sands excavation, surface and underground mining, frozen ground excavation, rock excavation, quarrying, and even underwater applications.

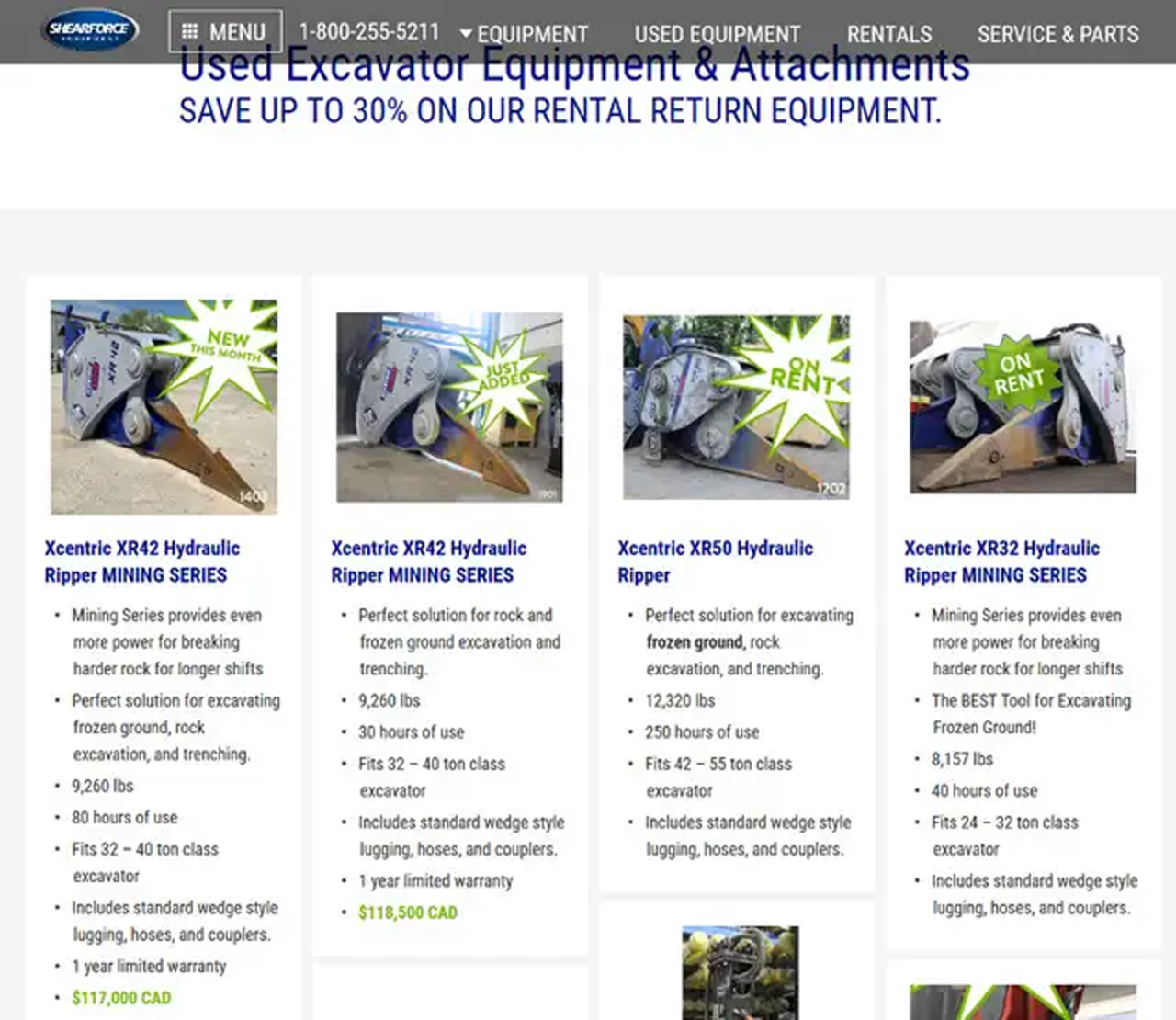

Visit the Xcentric Ripper page: https://www.shearforce.ca/equipment/xcentric-ripper/ to learn more and watch video of the Xcentric Ripper® Mining Series in action

WATCH THE VIDEOS COPY AND PASTE OR CLICK LINK:

NEW COST OVER $300,000.00 TAKE IT FOR $80,000.00 AND WE WILL SHIP QUICKLY = HAVE ON THE JOB NEXT WEEK

THIS UNIT WILL FIT THE FOLLOWING MACHINES WITH A HYDRAULIC PIN GRABBER COUPLER:

Case CX800

Caterpillar 365B L w/ VB Link Caterpillar 365C w/ Reach Linkage Caterpillar 375 Caterpillar 375 w/ Mass Linkage Caterpillar 375 w/ Reach Linkage Caterpillar 375CL Caterpillar 385B Caterpillar 385B Caterpillar 385B L

Hitachi Zaxis 650LC-3 BE Arm Hitachi Zaxis 650LC-3 H Arm Hitachi Zaxis 670LCH-3 BE Arm Hitachi Zaxis 670LCH-3 H Arm Hitachi Zaxis 800 & BE Hitachi Zaxis 850-3 BE Arm Hitachi Zaxis 850-3 H Arm Hitachi Zaxis 850LC-3 Hitachi Zaxis 850-LC-3 BE Arm Hitachi Zaxis 850-LC-3 H Arm Hitachi Zaxis 870H-3 BE Arm Hitachi Zaxis 870H-3 H Arm Hitachi Zaxis 870LCH-3 BE Arm Hitachi Zaxis 870LCH-3 H Arm Hitachi Zaxis 870LCR-3 BE Arm Hitachi Zaxis 870LCR-3 H Arm Hitachi Zaxis 870R-3 BE Arm Hitachi Zaxis 870R-3 H Arm

John Deere 600CLC & ME John Deere 650DLC John Deere 710G Std or Ext Stick John Deere 710J Std or Ext Stick John Deere 800 C & ME John Deere 850D LC

Kobelco SK850LC

KOMATSU PC600 PC600LC-6 PC600LC-7 PC600LC-8 PC600LC-8 PC650SE-3 PC650-6 PC750-6 PC750-6 PC750SE-6 PC800LC-7

Link-Belt 800 QUANTUM Link-Belt 8000 QUANTUM Link-Belt 8000 QUANTUM MASS

Volvo EC700B Volvo EC700C VOLVO EC800